Products

Product Description

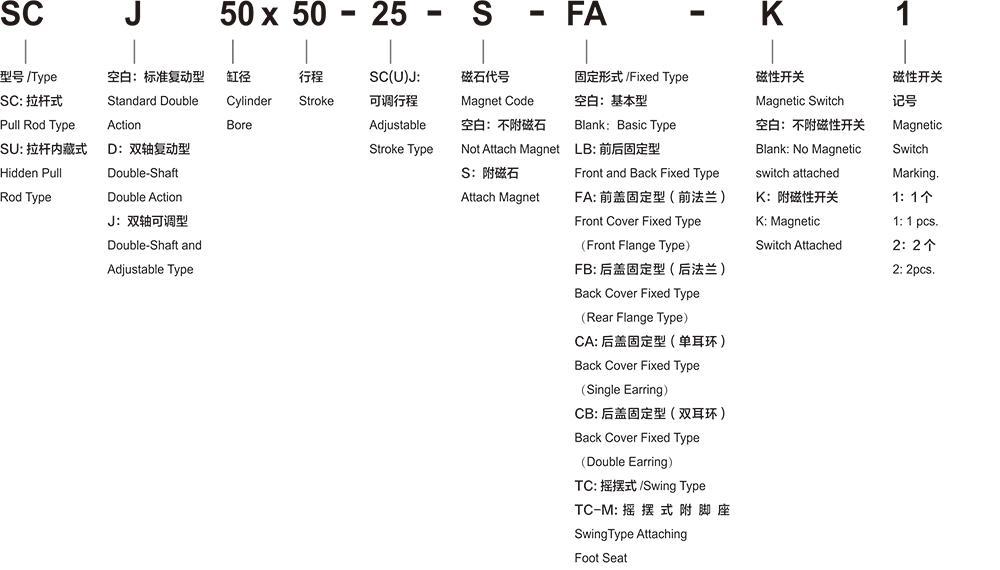

Ordering Code

Specification

| Bore(mm) | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

| Motion Pattern | Double Action | ||||||

| Working Medium | Air | ||||||

| Fixed Type | Basic Type.FA Type.FB Type.CA Type.CB Type.LB Type.TC Type.TC-M Type | ||||||

| OperatingVoltage Range | 1~9Kgf/cm² | ||||||

| Ensured Pressure Resistance | 13.5Kgf/cm² | ||||||

| Operating Temperature Range | 0~70℃ | ||||||

| Operating SpeedRange | 500~800mm/s | ||||||

| Buffer Fom | Adjustable Buffer | ||||||

| Buffer Travel | 20 | 25 | |||||

| JointPipe Bore | G1/8 | G1/4 | G3/8 | G1/2 | |||

SCD、SCJ Fixed Type:FA.FB.LB.TC.TC-M.

Cylinder Theory Output Sheet

| Cylinder I.D. (mm) | 32 | 40 | 50 | 63 | 80 | 100 | 125 | ||||||||

| Piston Rod O.D. (mm) | 12 | 16 | 20 | 20 | 25 | 25 | 32 | ||||||||

| Motion Pattern | Double Action | ||||||||||||||

| Pressure Side | Pull Side | Pressure Side | Pull Side | Pressure Side | Pull Side | Pressure Side | Pull Side | Pressure Side | Pull Side | Pressure Side | Pull Side | Pressure Side | Pull Side | ||

| Compression Area(cm²) | 8.04 | 6.9 | 12.56 | 10.55 | 19.63 | 16.49 | 31.17 | 28.03 | 50.26 | 45.36 | 78.53 | 73.62 | 122.7 | 114.6 | |

| Air Pressure(Kgf/cm²) | 1 | 8.04 | 6.9 | 12.56 | 10.55 | 19.63 | 16.49 | 31.17 | 28.03 | 50.26 | 45.36 | 78.53 | 73.62 | 122.7 | 114.6 |

| 2 | 16.08 | 13.8 | 25.12 | 21.1 | 39.26 | 32.98 | 62.34 | 56.06 | 100.52 | 90.72 | 157.06 | 147.24 | 245.4 | 229.2 | |

| 3 | 24.12 | 20.7 | 37.68 | 31.65 | 58.89 | 49.47 | 93.51 | 84.09 | 150.78 | 136.08 | 235.59 | 220.86 | 368.1 | 343.8 | |

| 4 | 32.16 | 27.6 | 50.24 | 42.20 | 78.52 | 65.96 | 124.68 | 112.12 | 201.04 | 181.44 | 314.12 | 294.48 | 490.8 | 458.4 | |

| 5 | 40.20 | 34.5 | 62.80 | 52.75 | 98.15 | 82.45 | 155.85 | 140.15 | 251.30 | 226.80 | 392.65 | 368.10 | 613.5 | 573.0 | |

| 6 | 48.24 | 41.4 | 75.36 | 63.30 | 117.78 | 98.94 | 187.02 | 168.18 | 301.56 | 272.16 | 471.18 | 441.72 | 736.2 | 687.6 | |

| 7 | 56.28 | 48.3 | 87.92 | 73.85 | 137.41 | 115.43 | 218.19 | 196.21 | 351.82 | 317.52 | 549.71 | 515.34 | 858.9 | 802.2 | |

| 8 | 64.32 | 55.2 | 100.48 | 84.40 | 157.04 | 131.92 | 249.36 | 224.24 | 402.08 | 362.88 | 628.24 | 588.96 | 981.6 | 916.8 | |

| 9 | 72.36 | 62.1 | 113.04 | 94.95 | 176.67 | 148.41 | 280.53 | 252.27 | 452.34 | 408.24 | 706.77 | 662.58 | 1104.3 | 1031.4 | |

Stroke

| Bore (mm) | Standard Stroke | Max.Stroke | Permissible Stroke |

| 32 | 25 50 75 100 125 150 175 200 250 300 350 400 450 500 | 1000 | 2000 |

| 40 | 25 50 75 100 125 150 175 200 250 300 350 400 450 500 600 700 800 | 1200 | 2000 |

| 50 | 25 50 75 100 125 150 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1200 | 2000 |

| 63 | 25 50 75 100 125 150 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 80 | 25 50 75 100 125 150 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 100 | 25 50 75 100 125 150 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 125 | 25 50 75 100 125 150 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

Please contact with our company if your cylider stroke is special.

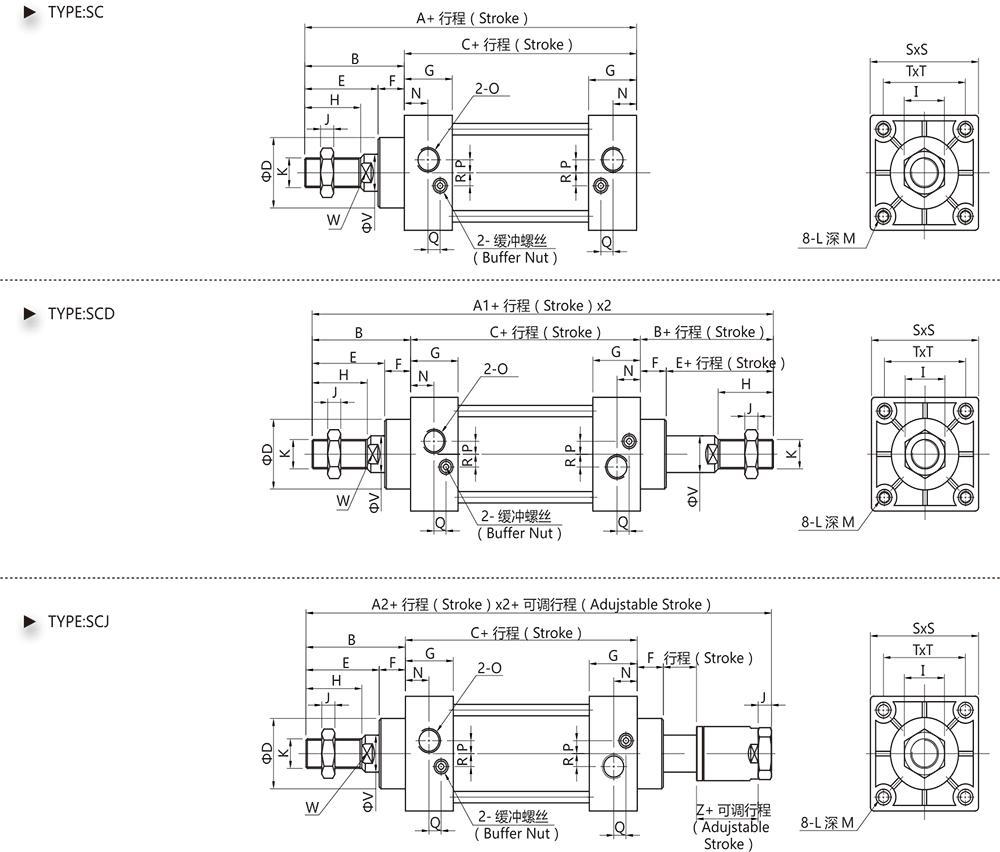

Overall Dimension

Dimension Sheet

| Symbol/Bore(mm) | A | A1 | A2 | B | C | D | E | F | G | H | I | J | K | L |

| 32 | 140 | 187 | 182 | 47 | 93 | 25.5 | 32 | 15 | 27.5 | 22 | 17 | 6 | M10×1.25 | M6 |

| 40 | 142 | 191 | 185 | 49 | 93 | 30 | 34 | 15 | 27.5 | 24 | 17 | 7 | M12x1.25 | M6 |

| 50 | 150 | 207 | 196 | 57 | 93 | 35 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16×1.5 | M6 |

| 63 | 153 | 210 | 199 | 57 | 96 | 35 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16×1.5 | M8 |

| 80 | 183 | 258 | 242 | 75 | 108 | 45.5 | 54 | 21 | 33 | 40 | 26 | 10 | M20x¹.5 | M10 |

| 100 | 189 | 264 | 248 | 75 | 114 | 45.5 | 54 | 21 | 33 | 40 | 26 | 10 | M20×1.5 | M10 |

| 125 | 218 | 312 | 286 | 94 | 124 | 55 | 64 | 30 | 33 | 45 | 35 | 11 | M27×2 | M12 |

| 160 | 311 | 312 | 418 | 143 | 168 | 63.5 | 103 | 40 | 50 | 72 | - | 12 | M36×2 | M16 |

| Symbol/Bore(mm) | M | N | o | P | Q | R | s | T | V | w | Z |

| 32 | 9.5 | 12.5 | G1/8 | 3.5 | 7.5 | 7 | 45 | 33 | 12 | 10 | 20 |

| 40 | 9.5 | 13.5 | G1/4 | 6 | 8.2 | 9 | 50 | 37 | 16 | 14 | 20 |

| 50 | 9.5 | 13.5 | G1/4 | 8.5 | 8.2 | 9 | 62 | 47 | 20 | 17 | 21 |

| 63 | 9.5 | 13.5 | G3/8 | 7 | 8.2 | 8.5 | 75 | 56 | 20 | 17 | 21 |

| 80 | 11.5 | 16.5 | G3/8 | 10 | 9.5 | 14 | 94 | 70 | 25 | 22 | 20 |

| 100 | 11.5 | 16.5 | G1/2 | 11 | 9.5 | 14 | 112 | 84 | 25 | 22 | 20 |

| 125 | 12 | 16.5 | G1/2 | 10 | 7.5 | 10 | 140 | 110 | 32 | 29 | 26 |

| 160 | 12 | 25 | G1/2 | 9 | - | - | 180 | 140 | 40 | 36 | 26 |

Keywords:

Air treatment

Control components

Actuators

Gas control valves

Auxiliary components

Needle Textile Machinery

Micro Solenoid Valves